An 8-gram actuator – a device that converts energy and signals into movement – that operates as artificial muscles lifted 8 kilograms while maintaining human-like hand movements

Technology

27 July 2022

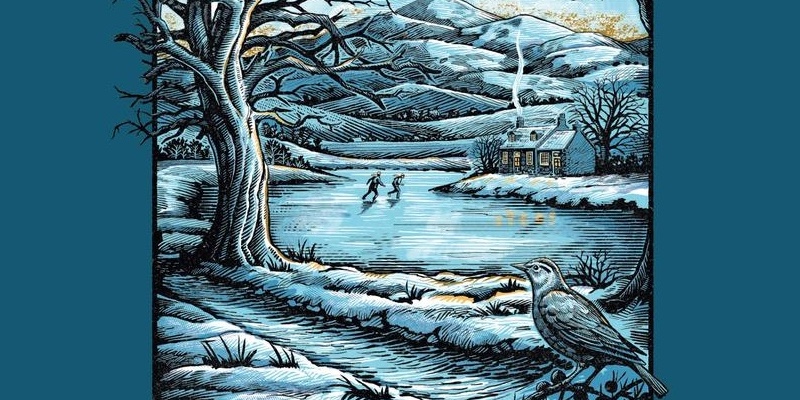

GRACE actuator membranes are 3D printed from a resin that enables them to stretch and contract like a human muscle Italian Institute of Technology

Tiny actuators – devices that convert energy and signals into movement – that operate as artificial muscles could lift up to 1000 times their own weight, according to research that may one day lead to robots with human-like grips.

Corrado De Pascali and his colleagues at the Italian Institute of Technology have developed 3D-printed artificial muscles, created from actuators that convert energy into movement by inflating the artificial muscles. “We started from the traditional artificial muscle and developed a new class of artificial muscles made of a single monolithic component,” says De Pascali.

The actuator membranes, called GeometRy-based Actuators that Contract and Elongate (GRACE), are 3D printed from a flexible resin that enables them to stretch and contract like a human muscle. The membrane was designed using a mathematical model created by the researchers.

The GRACE actuators are different to previous generations of artificial muscles because they contain pleats in their membrane that fold and unfold, giving the artificial muscles more strength and flexibility.

Depending on the material used to make the actuator and the material’s thickness, some actuators could lift relatively heavy items. When put to the test, one 8-gram actuator lifted 8 kilograms.

The actuators can also be combined to mimic real-life muscles and body parts. The researchers linked 18 different-sized actuators to make a robotic hand with a wrist. By applying pressure to the different actuator membranes, the hand could bend its fingers, twist its palm and rotate at the wrist.

“The design of the GRACE is interesting and novel, providing easy antagonistic operation by design,” says Jonathan Aitken at the University of Sheffield, UK.

Aitken believes that one of the most innovative elements is the choice of flexible resin for the actuator, which gives a greater range of movement than the stiffer resins used up until now. Nevertheless, Aitken says this flexible resin could be developed even further. “The more novel resins that can be developed with excellent tensile properties will increase the range of capabilities of devices printed using them,” he says.

Journal reference: Science Robotics, DOI: 10.1126/scirobotics.abn4155

More on these topics: